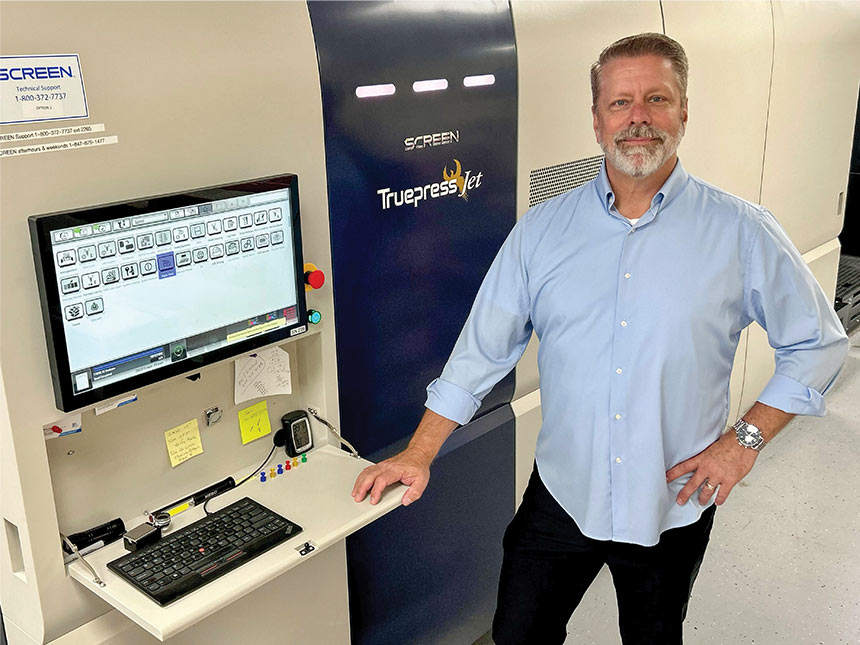

The first worldwide installation of the SCREEN Truepress JET 560HDX took place in the summer of 2024 at Art & Negative. The installation has proven to be a game-changer for the full-service print provider who offers a number of printing, finishing, mailing and fulfillment services—all of which are performed on site at the company’s 60,000-square-foot facility in Lanham, Maryland.

Art & Negative’s relationship with SCREEN Americas dates back to 1981 when the family-owned company was strictly a prepress shop and invested in several SCREEN drum scanners and SCREEN’s signature Sigmagraph systems. With the arrival of CtP, Art & Negative was forced to reconsider its position in the marketplace and in 2001 it made the transition from a prepress operation to a full-service commercial printer. In 2002 Art & Negative began offering mailing and fulfillment services and by 2005 it expanded its operations to include digital printing and die-cutting applications.

The twenty-first century has found Art & Negative capitalizing on its direct mail capabilities and acquiring customers in the healthcare industry—an industry where data security is paramount. It needed technology capable of producing complex variable data to live up to Art & Negative’s SOC 2 Type 2 map to HITRUST Compliance certification. SCREEN, like Art & Negative, had changed with the times and in March 2021 installed the Truepress JET 520HD AD in the printer's facility.

A second, more advanced digital inkjet roll-fed press was needed at Art & Negative to keep up with the demand of the company’s new clients as well as the ones they had been serving for decades. Thus, the very first Truepress JET 560HDX was installed at Art & Negative.

Now a full-service, in-house powerhouse with two SCREEN high-speed, roll-fed inkjet presses operating simultaneously, Art & Negative has the ability to shave days off its turnaround times and produce work that resembles that of offset in terms of quality, using only one operator per shift. Its customers now have near-bottomless choices when it comes to substrates and versioning. Whether it’s direct mail, confidential letters, catalogs, brochures or books, small and large jobs requiring paper up to 120 pounds with complex personalization embedded in every piece, Art & Negative is equipped with the technology to meet these demands.

Welcome to another edition of Inkjet IQ where you’ll find the latest news from SCREEN Americas.

One of the most exciting things to happen this past year was the first worldwide installation of the SCREEN Truepress JET 560HDX, which took place at Art & Negative in Lanham, Maryland. A long-time SCREEN customer, Art & Negative has weathered many changes in the printing industry over the decades and we are proud to have had them as our partner since 1981.

Other Truepress JET 560HDX installations are also on the horizon including two new commitments from VISOgraphic of Addison, Illinois, and Sandy Alexander of Clifton, New Jersey. These companies join MOSAIC of Cheverly, Maryland; Admail West of Sacramento, California; and Graphic Village of Cincinnati, Ohio, in their commitments to the latest high-speed inkjet technology from SCREEN.

Creating Your Future in Print was our theme at Labelexpo Americas and PRINTING United Expo held in Chicago and Las Vegas respectively in September 2024. As more and more printers incorporate inkjet technology into their pressrooms or switch to it entirely, SCREEN Americas continues to find better ways to accommodate its customers’ needs as they aim to achieve greater returns with increased capacity and tackle their challenges in finding skilled labor.

As always, our door is open to new ideas and we encourage your feedback anytime.

Ken Ingram

Embraced with the theme Creating Your Future in Print, attendees at PRINTING United Expo 2024 and Labelexpo Americas 2024 experienced SCREEN Americas’ unwavering commitment to providing customized solutions to printers looking to seamlessly transition—either partially or fully—from traditional web offset equipment and toner devices to digital inkjet technology.

At PRINTING United Expo in Las Vegas, attendees had a chance to see the Truepress JET S320, a digital inkjet sheetfed press that delivers exceptional color using 1,200 x 1,200 dpi at a speed up to 150 spm. The Truepress JET S320 has the ability to print directly onto offset coated paper and can support heavy stock. It also offers one- and two-sided printing with variable capabilities. As a standalone printing system or when combined with roll-fed digital inkjet technology, the Truepress JET S320 can offer printers the ability to provide multiple solutions for their customers.

Printers who ventured to the Donald E. Stephens Convention Center in Chicago for Labelexpo Americas explored various samples of prime and industrial labels from SCREEN’s flagship label press, the Truepress LABEL 350UV SAI, which offers CMYK, white, blue and orange inks. The press is capable of printing on multiple substrates and can achieve opacity on metallic and transparent materials. It also manufactures labels that meet indoor and outdoor UL certification requirements and can print eleven rolls in one day with only one operator in a single shift.

Attendees at Labelexpo also had the opportunity to inspect gusset bags, center seal bags and stand-up pouches produced from the Truepress PAC 830F plus various paper packages from the Truepress PAC 520P. Both presses from the PAC series use aqueous inks.

By installing SCREEN technology, those offering commercial, direct mail, publishing, label, flexible packaging, and paper packaging applications were able to imagine their futures serving an expanded marketplace with increased capacity, improved workflow, and a reduced workforce.

VISOgraphic and Sandy Alexander join MOSAIC of Cheverly, Maryland; Admail West of Sacramento, California; Graphic Village of Cincinnati, Ohio; and Art & Negative of Lanham, Maryland, among the companies turning to the latest high-speed, roll-fed inkjet technology from SCREEN.

The intent to purchase the Truepress JET 560HDX by VISOgraphic, a business-to-business, full-service commercial print provider located in Addison, Illinois, marks the company’s first entry into roll-fed inkjet technology.

Founded in 1946, VISOgraphic’s work spans a wide range of products including folding carton and packaging, variable direct mail, and web-to-print collateral management systems. Verticals served include travel and leisure, automotive, distribution, pharmaceutical, and nonprofit organizations.

Currently, 65% of the company’s workload is printed on offset equipment. The new press is expected to assume some of this production especially in direct mail projects.

It was at drupa 2024 where the team at Sandy Alexander, a full-service print provider founded in 1963 and headquartered in Clifton, New Jersey, was introduced to the Truepress JET 560HDX and couldn’t help but notice the press’s superior color quality.

After spending months investigating multiple inkjet web solutions, the leaders at Sandy Alexander turned to SCREEN Americas for a solution to meet their customers’ ongoing requests for smaller, yet highly personalized runs with 2-sided variable capabilities.

Sandy Alexander offers a wide range of services to the architectural, automotive, beauty, dining, healthcare, higher education, life sciences, retail, and travel industries.

Question: How many SCREEN Inkjet Innovation Centers are there worldwide? See Answer

Projects at Allegra Print·Bind·Ship in Plymouth, Michigan, that once took 50 hours to complete now take as little as 10 hours thanks to the Truepress JET 520HD+, which was installed at the company’s 35,000 sq. ft. facility last spring. The installation led to Allegra eliminating three toner devices and a 6-color, 40-inch sheetfed press.

The technology complements the company’s business model by providing customers with strategic marketing solutions that include variable and static print production on multiple substrates. The technology also seamlessly integrated with the company’s sophisticated finishing equipment used for its publishing applications: perfect-binders, coil-binders and saddle-stitchers.

Weekley’s Mailing Service of Berea, Ohio, has been providing mailing insertion services for the better part of 76 years. A HIPAA-compliant company, it needed a press that could fulfill its promise of error-free mailing. The complex variable capabilities of the Truepress JET 520NX have set a new standard for the Ohio-based company.

Weekley’s Mailing Service prints and inserts many data-sensitive letters for various clients—both direct and as a provider to other printers. With an in-line sheeting solution to facilitate automation, the company can now transition to 18-inch rolls of 60 or 70 lb. stock and increase production from 246 feet per minute, 1-up printing on its current roll-fed device to 492 feet per minute, 2-up printing on the Truepress JET 520NX.

French magazine Pap Argus, which hosted its annual La Nuit du Papier (The Night of Paper) award ceremony in Paris last April, recognized the Truepress PAC 520P as worthy of the Pap’Awards de l’Impression for Transformation in Packaging: Paper & Cardboard. The judges were very impressed by the press’s ability to accommodate multiple paper substrates.

A panel of 30 experts from the French packaging industry selected SCREEN to receive the Innovation: Industrial Efficiency award at ALL4PACK, which took place in Paris last November. The credit goes to the cutting-edge capabilities of the Truepress PAC 830F, which proved to offer industrial-grade efficiency, flexibility and sustainability to the packaging market.

Check out SCREEN Americas' LinkedIn posts highlighting customer interviews, installations and more!